3D Printing Australia: Making Things Easier in Dental Industry

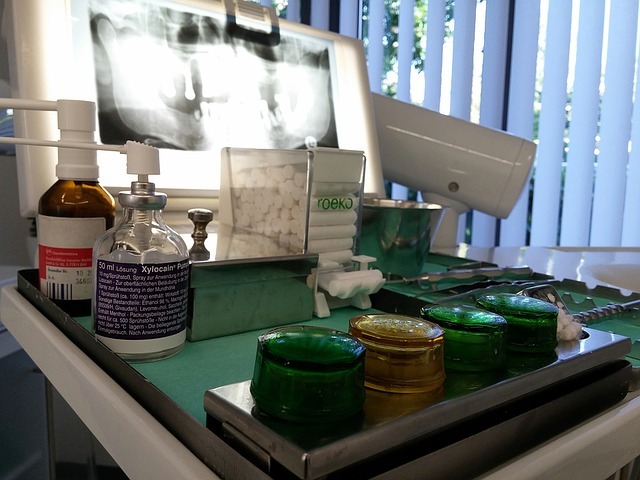

3D printing Australia has influenced many industries, but few exist to benefit as much as the medical fields that include the dental industry.

3D printing tools flourish in an environment where our distinctive bodies require custom solutions. As an end result, the dental industry is in a rapid digital revolution with digital workflows bringing in increased efficiency, consistent high-quality, and lower fees to dental labs and practices.

3D Printing Australia Revolutionizing the Dental World

Read on to find out five ways in which the digital workflows are transforming the dental industry.

Low-Cost Mass Customization

While the dental industry has always needed high levels of customization, it has traditionally depended mostly on manual processes to create custom appliances. Now, digital workflows allow mass customization in a steady, automated way, needing less labor and sustaining lower costs.

Everybody has a dentition—the model of development and composition of teeth—unique to them. Dental signs must, therefore, be rendered to match each specific patient’s anatomy. With conventional manual workflows, the value of the finished products is highly reliant on the skills of a technician. Attaining constant and high-quality dental products with a lot of potential sources of mistake is incredibly complicated and expensive.

Digital Implantology

Digital tools can augment complex surgical processes. CBCT, virtual assignment planning, and surgical instructions are becoming the latest standards of treatment in implantology. With such, the precision of implant placement during a surgical procedure is all but assured, the threat of surgical difficulties falls, and clinical outcomes are improved overall.

To create a guide, implantologists merge intraoral scan data of a patient’s dentition as well as the composition of the patient’s osteotomy from a cone beam scanner. Basing on the anatomical data, doctors utilize CAD software to plan treatment with high precision and use a three-dimensional printer to deliver a guide that is set to be used in surgery.

Digital Dentures

Conventional denture manufacturing is a time-exhausting and labor-demanding analog workflow that entails multiple patient visits and production stages. It is a complicated craft with a steep understanding twist and dental labs gradually work hard to find technicians with the sophisticated skills and knowledge required to deliver them.

Dentures are among the latest inventions in digital dentistry. They give a cost-effective and cost-effective manufacturing resolution and a major move toward the overall generalization of the dental laboratory production process.

Denture construction with the digital workflow contains fewer steps and less inconsistency, causing in a more stable workflow for a high-value end product every time. Denture designs are also shareable, reusable, modifiable, and simple to reproduce with 3D printing. The inexpensive hardware, lower material prices, and less labor all support to a substantial cost benefit over their handcrafted equivalents.

Better Experience for Patients

At the end of the day, it would the patients who will gain the most from the developments in digital dentistry.

Start Off with the visit to the orthodontist or dentist, being able to envision a dental process can be as comforting for the patient as it is advantageous for the medical practitioner. Virtual therapy planning, indicative wax-ups, and highly comprehensive replicas can assist patients to see and appreciate the treatment they will be getting in great detail, lowering anxiety and improving patient approval.