How to Make Use of Wood Filaments for 3D Printing Services?

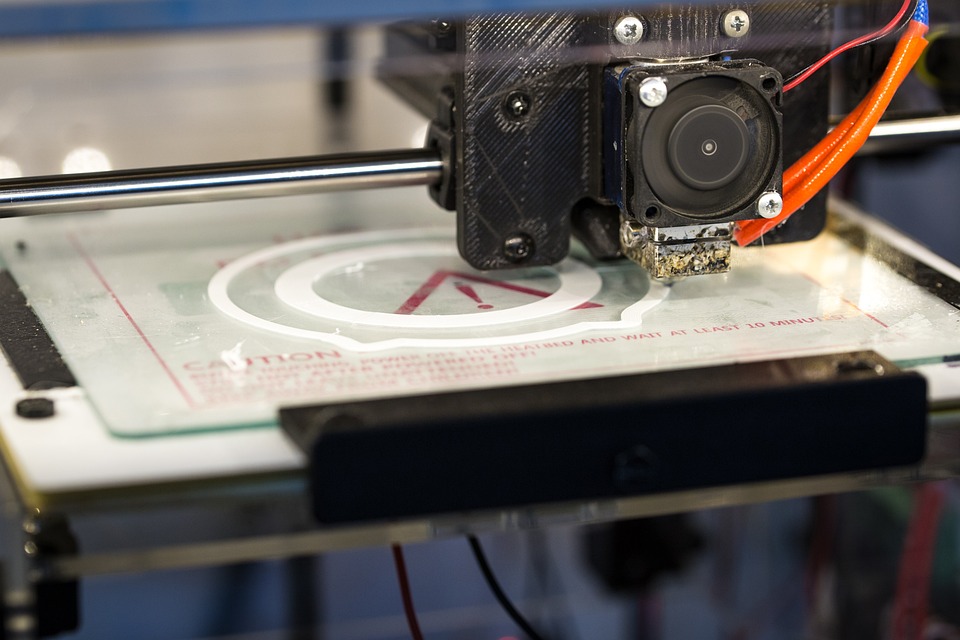

Fabrication centers offering 3D printing services often say that working with wood filament is not always a breeze. Newcomers in this industry would be purchasing a roll of wood filament with the high hopes of printing with it, in the same manner, they would any other PLA filament.

But they are up for some disappointment there because it is a mistake. To successfully carry out a printing job with wood filament, you need patience and lots of it. You also need to couple that up with advanced technical printing skills.

We’ve compiled a list of valuable tips for this in the hopes that they will be of significant help to you get started with wood filament printing.

1. Make Use Of A Bigger Nozzle

To begin with, the bulk of wood filaments will have the feel and appearance of medium density fiberboard. Depending on the mode you have, you could also see some huge black splotches in the filament, which are all completely natural.

When using wood filaments, however, you should use a larger nozzle. This should help in keeping the big specs from clogging up within your nozzle.

It may seem counterintuitive to use a 6 mm nozzle, but bigger and wider nozzles are more advantageous to use because they are less likely to clog in the long run.

And you’re not alone if you don’t like the way the layers look with a larger nozzle. If you don’t like how the larger layering would appear, remember that you can opt to send it away after printing is done.

Long-time providers of 3D printing services say that it is not fun to see your nozzle getting clogged with wood filament. What you’ll be left with is a dark, burnt mess to clean up if you don’t spot the issue right away, since the filament will likely get burned inside the extruder.

2. Make it a habit to remove the filament from the hotend when not printing.

Next, when turning off the printer or interrupting the ongoing printing work for some reason, see to it that you always remove or take away the filament from the printer head.

Otherwise, it runs the risk of the filament wood fibers burning up. If this happens, it will result in a black gooey mess right inside your printer head. This necessitates you to use a cleaning filament in vacuuming out the extruder.

Cleaning filament would save you a significant amount of time that you might have wasted unclogging your extruder.

Cleaning the filament will even clear away a considerable amount of gunk from the inside of your printer. You’ll remember how useful it is after running it into your printer once.

3. Maintain the Lowest Possible Temperature.

If you’re new to using wood filaments, you might be fascinated by the idea of printing out a darker burnt wood finish which can be made possible by increasing the temperature.

The problem here, according to those who are seasoned providers of 3D printing services, is that there are a handful of wood filaments that are extremely sensitive to high temperatures, that even just a single degree off and you will be in for a really bad time. If the fine wood particles ignite in your hot end, it could result in a nasty clog.

As a result, many people who use wood filaments will no longer bother looking for the spot where the melt temperature will lay the groundwork for a darker wood finish. Instead, consider finding a wood stain that is capable of delivering the same effect.